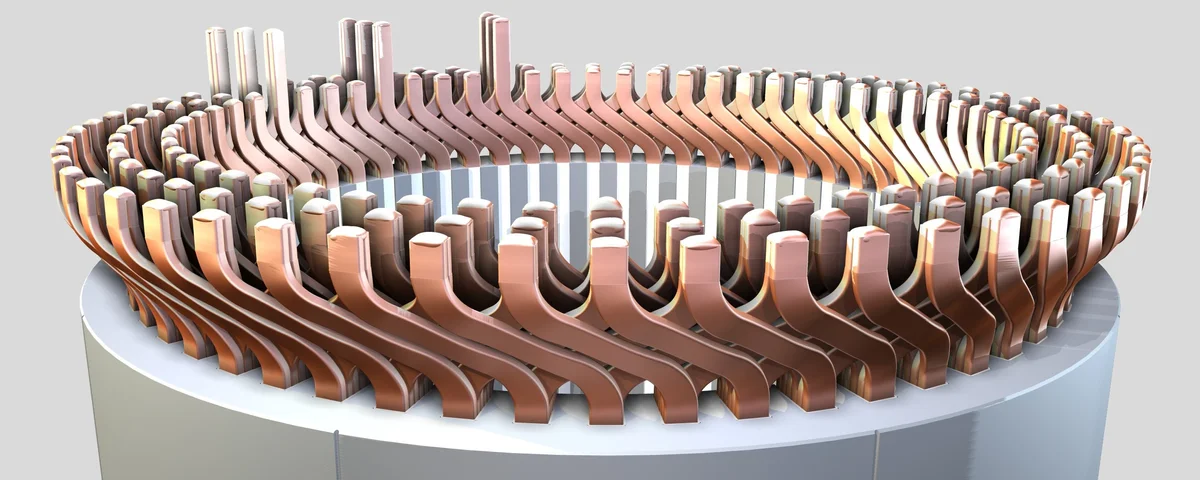

Hairpin machines have become an integral part of automated production lines, offering seamless integration and enhancing efficiency in hairpin manufacturing processes. These machines are designed to work harmoniously with other automated systems, such as robotic arms, conveyors, and quality control equipment. In this article, we will explore how hairpin machines seamlessly integrate into automated production lines and contribute to improved productivity and streamlined operations.

- Efficient Material Handling hairpin bender machine are designed to seamlessly integrate with robotic arms and material handling systems. This integration enables automated loading and unloading of raw materials and finished hairpin coils, eliminating the need for manual intervention. Robotic arms can precisely pick up and position the materials, feeding them into the hairpin machine for further processing. This efficient material handling minimizes downtime, reduces labor costs, and improves overall productivity.

- Streamlined Workflow Hairpin machines are synchronized with other equipment in the production line, ensuring a smooth and uninterrupted workflow. Automated conveyors transport materials from one processing station to another, seamlessly transferring the hairpin coils between different machines and workstations. The synchronized workflow minimizes bottlenecks, optimizes production capacity, and reduces the risk of errors or inconsistencies that may arise from manual handling.

- Real-time Quality Control Hairpin machines can be integrated with quality control systems, enabling real-time monitoring and inspection of the hairpin coils. Automated vision systems and sensors can inspect the coils for dimensional accuracy, surface defects, and other quality parameters. Any deviations or anomalies detected during the inspection process can trigger immediate corrective actions, ensuring that only high-quality hairpin coils are passed through the production line. This integration of quality control measures enhances product consistency and customer satisfaction.

- Data Collection and Analysis Hairpin machines can be connected to data collection systems that gather information about the production process. This data includes production rates, cycle times, machine performance, and energy consumption. By analyzing this data, manufacturers can identify areas for improvement, optimize machine settings, and streamline production operations. The integration of data collection and analysis tools facilitates data-driven decision-making, leading to increased efficiency and productivity.

- Scalability and Adaptability Hairpin machines are designed to be scalable and adaptable to changing production demands. As part of an automated production line, these machines can easily accommodate changes in production volumes, product specifications, and customization requirements. With the ability to adjust settings, change tooling, and reprogram machine parameters, hairpin machines offer flexibility and agility in response to market demands, ensuring optimal utilization of resources and maximizing production efficiency.

- Remote Monitoring and Control Hairpin machines can be equipped with remote monitoring and control capabilities, allowing operators to monitor and manage production processes from a central control room. This remote access enables real-time monitoring of machine performance, immediate troubleshooting, and efficient maintenance scheduling. Remote monitoring and control enhance operational efficiency by reducing downtime, minimizing response time to issues, and optimizing machine utilization.

In conclusion, hairpin machines seamlessly integrate into automated production lines, contributing to improved productivity, streamlined operations, and enhanced quality control. The efficient material handling, streamlined workflow, real-time quality control, data collection and analysis, scalability, adaptability, and remote monitoring and control capabilities of hairpin machines ensure smooth and efficient hairpin production. By embracing the benefits of seamless integration, manufacturers can optimize their manufacturing processes, reduce costs, and meet the demands of the hairpin industry effectively.